CAE in Bio-Mechanics – Imagine Next ?

The Computer Aided Engineering (CAE) models for human bodies are now being used in automotive crash simulations to identify safety problems and find their solutions. They can simulate kinematics and injuries in response to a large impact such in a car crash

The simulation data is used to determine preventive and corrective measures, eventually improving human safety first, and then the quality of life in case of an unfortunate incident.

We have come a long way in a few years, with increasing computing power and human creativity.Now Let’s imagine next!

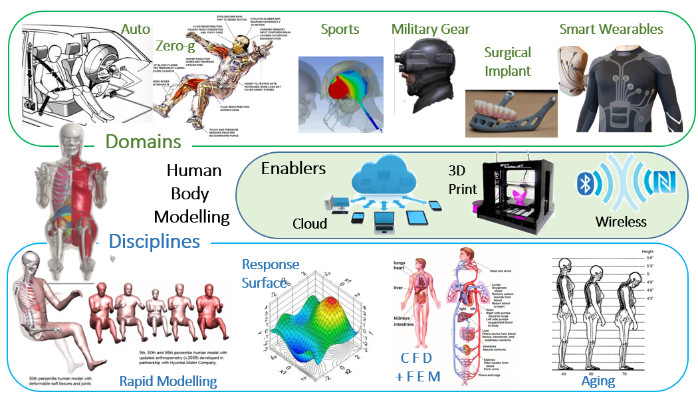

Emerging Disciplines

Current human body models are large, complex and expensive to create and deploy. Speed, accuracy and convenience will come from the following discipline developments.

- Morphing and scaling baseline models using few measurements, or an MRI/CT Scan.

- Parametric modeling based surrogate response surfaces for rapid offline design optimization,

- Probabilistic Modeling to address variations in human size and strength,

- Interactions of active and passive safety devices, and human response,

- CFD and FEM to model blood flow, Fluid-structures interaction

- Usable bio-materials handbook to support rapid human body, particularly skin models

- Aging simulation using time varying material models and mesh morphing,

- Realistic validation and calibration protocols.

Potential Domain Opportunities

There is a tremendous amount of opportunity to apply models in almost every domain.

Road Safety: Device Design Optimization for automobiles, and motorcycles

Medicine: Medical procedure simulation in domains such as routine surgery, orthopedic reconstruction, Medical devices & prosthetic design optimization, custom metal implants for broken bone repair, post implant aging simulation, hemorrhage simulation, …

Sports: Simulate events such as NFL concussion, and safety devices for Indy 500 and formula1.

Military and Space: Optimize gear for individual soldier, design the light weight personal protective devices: recoil of a shoulder fired weapon, Impact of explosions in close proximity, or even design of IED boots, simulate high-g maneuvers for military pilots, astronaut under zero-g or low-g conditions, post-traumatic medical qualification of soldiers, rehab program design , ….

Forensics: Computationally reconstruct an accident or a challenging crime scene investigation, to understand and verify hypothesis.

Smart wearables: To pick early signs of cardiac arrest or a stroke and communicate threat/risk

Enabling Technologies

Our ability to deploy discipline capability to realize success in various domains discussed above depends upon convergence of four few key enabling technologies.

3D Printing – to create custom designed part at point of use,

3D Visualization – for quick design and verification prior to 3D printing,

Cloud Computing – to harness high-speed processors and large storage from mobile devices,

Wireless Communication – to connect the engineer/doctor with the visualization/printing devices.

Business Opportunities

Although most of the research so far has been in R&D or academia. The area is about to explode in scope and value across the entire value chain – research, development, and application.

Model Research: Academia will be pushing the boundaries of discipline capability using Government and Industry sponsorship. Their product would be advanced methods, trained workforce, and possibly startups. The key to success is in research aligned with market pull, and a commercialization plan or a competent partner.

Model Adaptation and Commercialization: Engineering Service Providers will translate and accelerate the discipline(s) capability coming from academia into application in different domains. They will further develop the models, accelerate evolution, deploy multi-disciplinary competencies, generate domain specific capabilities, Cross-pollinate competencies and experience, provide design innovation, lead optimization, provide consulting and training, and a whole host of other commercial services, including adapting to new markets and global growth opportunities.

The key to success is in connecting the dots between disciplines and dom18ains and spreading the knowledge base across commercial, geographic and political boundaries, making an impact on lifestyle.

Model Application: Product OEMs are the end users of deployable models. They would use engineering capability to customize and optimize product design and differentiation for market share.

The key to success is partnerships with engineering service providers and guiding academic research.

I see an immediate use of these models in design optimization of safety devices such as seat belts and air bags, using surrogate response models for human beings and adaptive designs for various class of vehicles (bike to bus).

In Conclusion

We have come a long way in CAE applications to engineering over the last 30 years. Now, a completely new horizon of life form modelling awaits our imagination at the intersection of CAE simulation, 3D printing, advanced visualization, cloud computing, wireless networking, and biomaterial properties.

Author welcomes readers to engage in a dialogue on various thoughts presented here in and stir the imagination of whatever else is possible, appropriate, and worthy of human endeavor.

I can see a unicorn opportunity here, probably in the medicine domain.